IF IT LOOKS WORN, CORRODED, BROKEN

�OR MISSING�IT PROBABLY IS

By Geoffrey Pence,

Customer Service Manager, Twin Commander Aircraft

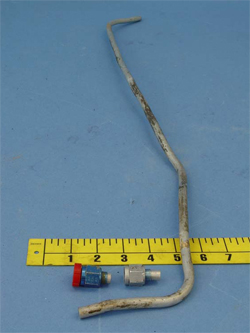

Hydraulic line was original equipment.

Support clamps had been removed sometime

in the past.

You�ve heard the old saw, �If it sounds too good to be true, it probably is.� There�s a corollary that can be applied to aircraft parts and maintenance: �If it looks suspect, it probably is.�

A Twin Commander 500B with seven aboard was inbound for landing when the pilot noticed that the hydraulic pressure gauge needle was fluctuating. He lowered the landing gear, but the left main gear did not extend. After unsuccessfully attempting to force the left main gear down by �bouncing� off the runway on the right main, he used the emergency blow-down bottle, but that too, proved unsuccessful. He elected to land, and on the landing rollout the left main collapsed.

The pilot�s problems began when a hydraulic line in the left engine nacelle ruptured, allowing fluid in the hydraulic reservoir to pump overboard. Subsequent inspection of the line showed that it failed at a point where it flares going into a fitting. Wear was evident near bends in the line where two clamps securing it to the airframe had previously been located but at some point were removed.

On-condition is an effective maintenance strategy, provided that the parts and components in question are inspected properly and thoroughly as described in factory service instructions. Twin Commander Service Information 236, titled �Inspection and Replacement of Fluid Lines� and issued August 2, 1995, recommends replacement of all firewall-forward fluid hoses at least every 10 years, and inspection and repair or replacement of all tubing and fittings that appear to be worn, damaged, or corroded.

The document also calls for inspection of all fuel, oil, and hydraulic hoses, tubes, and fittings throughout the airplane at each annual inspection. Any worn or damaged hoses should be replaced regardless of age, and any worn, damaged, or corroded tubing and fittings should be repaired or replaced.

Fitting end of line shows significant wear.

A simple inspection of the line, per Service Information 236, would have revealed that the clamps were missing. Service Information 236 calls for clamps to be tight on replacement hoses. The broken line was not a replacement hose, but common sense should have led a technician to check the clamps on the line in question. Even if the missing clamps were overlooked in an inspection, the overall poor appearance of the line should have prompted a more detailed investigation. The operator reported that the line had never been replaced since the airplane was new. Total time on the airframe was reported to be more than 18,000 hours.

Factory service documents provide mandatory and recommended inspection, repair, and replacement instructions, but they do not and cannot cover every piece, part, component, and procedure. Experience, logic, and common sense must be applied to ensure that any inspection and follow-up actions are comprehensive and thorough. If a technician sees something that raises a question, at the very least it calls for closer scrutiny. After all, if a hose, tube, line, fitting, or clamp looks bad, it probably is.

Discuss this article in the forums...